Dredging in Unstable Terrain Is a Persistent Challenge

Many dredging projects today take place in soft, unstable, and shallow environments such as marshes, floodplains, swamps, and silty riverbeds. These locations are increasingly targeted for restoration, sediment removal, and waterway maintenance due to growing environmental and infrastructure concerns. However, their soft soils, unpredictable water levels, and low load-bearing capacity present significant operational hurdles.

Traditional dredging equipment is often not designed to operate in these conditions. Standard excavators and barge-mounted systems can sink, get stuck, or become unstable, especially when deployed in areas where the ground is saturated or submerged. Attempting to modify conventional machines for these tasks often results in safety risks, project delays, and excessive wear on equipment.

This is where amphibious dredging services become essential. They utilize purpose-built equipment, such as the amphibious excavator dredge, which is specifically designed for soft terrain and shallow water operations. These machines are equipped with pontoons for flotation, extended tracks for stability, and the versatility to operate in both land and waterlogged environments. Key features include:

- Wide, low-ground-pressure tracks for traversing soft soils without sinking

- Buoyant pontoons that enable floating in shallow water

- Compatibility with specialized attachments for efficient amphibious excavator dredging

- Self-mobility across wetlands, canals, and marshy terrain without the need for external support platforms

Problem 1: Soft Soils That Cannot Support Heavy Equipment

Soft, saturated soils such as peat, clay, and silt are common in wetlands, swamps, and marshy regions—areas often targeted for environmental dredging or sediment removal. These types of terrain pose serious challenges for conventional heavy machinery, which is typically designed for firm ground. Standard tracked or wheeled excavators often sink or become immobilized in soft substrates, resulting in project delays, increased fuel consumption, and frequent equipment recovery efforts.

When conventional dredging systems are deployed in such environments, the risks include:

- Loss of traction and stability

- Machine submersion or tipping hazards

- Damage to the ground surface and the surrounding ecosystem

- Increased wear and strain on undercarriage components

To address these issues, amphibious dredging services deploy specialized machinery such as the amphibious excavator dredge. These machines are specifically designed for use in soft, semi-submerged environments. Key features that make them ideal for these conditions include:

- Buoyant pontoons that provide flotation support, allowing the excavator to remain stable even in water-saturated ground

- Wide, low-ground-pressure tracks that distribute weight evenly and prevent sinking

- Hydraulic extendable tracks that offer enhanced balance and surface contact on uneven or shifting terrain

- Adaptability to wet-to-dry transitions, which enables uninterrupted amphibious excavator dredging across mixed environments

By using equipment designed for mobility and flotation, amphibious dredging services ensure reliable operation in soft soil conditions where traditional machines fail.

Problem 2: Limited Access in Flooded or Isolated Locations

Dredging in remote or flood-prone areas presents unique logistical challenges. Locations such as disconnected channels, shallow floodplains, and partially submerged sites often lack road access or suitable launch points for standard dredging equipment. Moving traditional excavators or barge-based dredgers into these areas typically requires significant infrastructure development, such as building temporary roads or floating platforms, adding cost, time, and complexity to the project.

In these scenarios, the limitations of conventional equipment become apparent:

- Inability to operate in extremely shallow or fluctuating water levels

- Dependence on large transport vessels or cranes for relocation

- Restricted mobility between isolated sections of the job site

- Delayed deployment due to difficult terrain or lack of access roads

Amphibious dredging services address these access limitations with highly mobile and versatile machinery. A well-designed amphibious excavator dredge can navigate both land and water with ease, making it ideal for environments where entry points are limited or terrain changes frequently.

Key benefits of amphibious mobility include:

- Self-propulsion in marshes, wetlands, and shallow water

- No need for additional towing or support equipment

- Smooth transition between disconnected or flooded work zones

- Reduced site preparation and faster mobilization

With these advantages, amphibious excavator dredging emerges as the preferred solution for tackling inaccessible or fragmented dredging sites, where speed, flexibility, and terrain adaptability are crucial.

Problem 3: Environmental Sensitivity and Regulatory Constraints

Dredging in environmentally sensitive areas such as wetlands, wildlife reserves, and protected shorelines is often subject to strict regulatory oversight. These regions typically prohibit conventional land alteration methods that may disturb native habitats, water quality, or soil structure. Heavy machinery and large-scale access roads can cause irreversible damage to fragile ecosystems, making traditional dredging techniques unsuitable.

Permitting agencies and environmental guidelines commonly impose the following restrictions:

- No destruction of native vegetation or marshland surfaces

- Minimal ground disturbance and sediment resuspension

- Low-noise, low-emission equipment requirements

- Tightly controlled work zones to protect flora and fauna

Amphibious dredging services offer a practical and compliant alternative for working in these restricted zones. The use of an amphibious excavator dredge allows operators to perform necessary dredging tasks while minimizing ecological impact. These machines are designed to float and maneuver gently over soft terrain without the need for road construction or external support platforms.

Low-impact features that support amphibious excavator dredging in sensitive environments include:

- Wide tracks that distribute weight evenly, reducing soil compaction and habitat damage

- Flotation pontoons that allow work in shallow or submerged areas with minimal sediment disruption

- Precision dredging attachments for targeted sediment removal, reducing turbidity, and protecting aquatic life

- Ability to access sites without altering the landscape, avoiding the need for haul roads or staging areas

By integrating environmentally conscious equipment into their field operations, amphibious dredging services enable contractors to meet regulatory requirements while preserving the integrity of ecologically sensitive project sites.

Problem 4: Inefficiency in Multi-Phase Dredging Projects

Multi-phase dredging projects often require operations to transition between land-based excavation and in-water dredging. In conventional setups, this typically involves deploying different types of equipment for each phase—land-based excavators for shoreline work and barge-mounted systems for deeper areas. The constant switching between machines, repositioning of support equipment, and coordination between crews result in delays, added labor, and higher operational costs.

Key inefficiencies that arise in these projects include:

- Extended downtime during equipment changeovers

- Duplication of setup efforts for different terrain zones

- Increased fuel and labor costs due to mobilization logistics

- Limited access to shoreline areas with fluctuating water levels

Amphibious dredging services address these inefficiencies by utilizing equipment that can operate seamlessly across both land and water without interruption. An amphibious excavator dredge is specifically designed to perform seamless transitions between marshes, shorelines, and submerged zones, eliminating the need for multiple machine types.

Benefits of using amphibious excavator dredging in multi-phase projects include:

- One machine for all stages—from dry excavation to wet dredging

- Reduced downtime and faster phase-to-phase transitions

- Lower total project costs due to simplified logistics

- Improved scheduling and fewer weather-related disruptions

By streamlining operations across diverse terrain types, amphibious dredging services enhance project efficiency, reduce equipment requirements, and keep complex dredging schedules on track.

Solution Overview: What Sets Amphibious Excavator Dredging Apart

Amphibious excavator dredging is specifically designed to handle the operational demands of unstable terrain, shallow water, and soft-bottom environments. Unlike conventional dredging equipment, amphibious machines are engineered for mobility, stability, and versatility across both land and water. This makes amphibious dredging services the ideal solution for projects that require continuous access to wetlands, marshes, floodplains, and shallow channels.

At the core of this capability is the amphibious excavator dredge, which integrates several advanced features:

- Wide, sealed pontoons: These provide flotation and distribute the excavator’s weight evenly, preventing it from sinking in soft soil or waterlogged areas.

- Self-propulsion systems: Hydraulic or track-driven systems enable the machine to move independently through water, mud, and unstable terrain, eliminating the need for towing or external support.

- Hydraulic extendable tracks: These enhance balance and stability, allowing safe operation even in uneven or shifting environments.

- Corrosion- and abrasion-resistant construction: Ensures long-term durability in harsh dredging conditions.

In addition to its mobility and structural stability, the amphibious excavator dredge supports a range of specialized attachments that expand its capabilities, including:

- Dredging buckets for mechanical excavation

- Hydraulic cutters for breaking down compacted material or vegetation

- Slurry pumps for transferring sediment and fluids over long distances

- Clamshell and rake attachments for shallow or precision dredging applications

These combined features make amphibious excavator dredging highly effective for projects with changing water levels, limited access, and soft terrain, where traditional machinery would either fail or require costly adaptation. As a result, amphibious dredging services offer a flexible, all-in-one solution for complex dredging environments.

Industry Use Cases for Amphibious Dredging Services

The versatility and terrain-adaptability of amphibious dredging services make them ideal for a wide range of industries and public infrastructure projects. Whether the goal is environmental restoration, flood prevention, or sediment control, the ability to operate in soft soils and shallow waters gives these services a clear advantage over traditional dredging methods.

Key industry applications include:

- Wetland Rehabilitation: Amphibious dredging plays a crucial role in restoring degraded marshlands and swamps. Using an amphibious excavator dredge, crews can remove excess sediment, invasive vegetation, and debris without damaging the sensitive ground structure. This is crucial for promoting native habitat recovery and restoring water flow.

- River and Canal Desilting: Over time, sediment buildup in rivers and irrigation canals can obstruct water flow and reduce capacity. Amphibious excavator dredging enables precise removal of silt and organic matter even in narrow or shallow channels where barge-based equipment cannot operate.

- Stormwater Retention Pond Maintenance: Retention basins and detention ponds require regular dredging to maintain storage capacity and water quality. Amphibious equipment allows access to waterlogged, sloped, or vegetated areas without draining the pond, reducing both downtime and environmental disruption.

- Emergency Flood Mitigation: In flood-prone areas, quick dredging responses are essential to restore drainage and prevent overflow. Amphibious dredging services can be rapidly deployed in saturated flood zones to clear blockages, deepen flow paths, and reduce the risk of infrastructure damage.

These use cases demonstrate the value of a flexible, mobile solution like the amphibious excavator dredge, especially when conventional dredging equipment cannot reach or operate efficiently in difficult terrain.

Choosing a Reliable Amphibious Dredging Provider

Selecting the right contractor for amphibious dredging services is crucial to project success, particularly in environments with soft soils, waterlogged terrain, or stringent regulatory constraints. A reliable provider should not only offer access to specialized equipment, such as the amphibious excavator dredge, but also provide the technical expertise needed to adapt to changing field conditions and ensure environmental compliance.

One of the most important considerations is selecting project-specific equipment. Not all amphibious machines are alike—different models vary in weight capacity, reach, flotation capability, and attachment compatibility. Ensure that the dredging provider has equipment suited for the specific soil type, water depth, and sediment conditions of your site.

To evaluate a provider effectively, consider the following factors:

- Fleet capabilities: Does the contractor have a range of amphibious excavators with different sizes and configurations?

- Experience with similar terrain: Has the team worked on projects involving marshes, flood zones, or wetland restoration?

- Availability of specialized attachments: Are they equipped with pumps, cutter heads, and buckets appropriate for your dredging goals?

- Environmental and safety practices: Can they meet local regulatory requirements and demonstrate a low-impact work history?

Before hiring a contractor, ask these key questions:

- What type of amphibious excavator dredge will be used, and why?

- Can you provide examples of similar amphibious excavator dredging projects?

- What is your typical mobilization time for remote or emergency sites?

- How do you handle sediment disposal, site restoration, and regulatory reporting?

Solving Terrain Challenges Starts with the Right Equipment

Working in marshes, wetlands, flood zones, and other soft-soil environments presents challenges that conventional dredging methods simply can’t overcome. From limited access and environmental restrictions to unstable ground conditions, these projects require a specialized approach. Amphibious dredging services provide that solution—delivering mobility, efficiency, and low environmental impact through the use of advanced amphibious excavator dredges and expert-driven field execution.

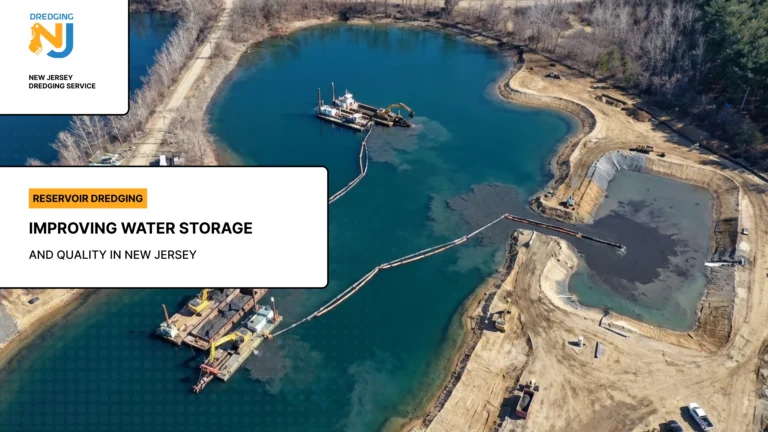

If your project site involves difficult terrain or sensitive ecosystems, partnering with a trusted provider is key. At Dredging NJ, we offer comprehensive amphibious excavator dredging services tailored to New Jersey’s unique waterways and land conditions. Contact our team today to schedule a site evaluation and discover how our amphibious equipment can streamline your next dredging project.