In abrasive slurry pumping applications, the choice between rubber and metal linings is far more than a technical detail; it’s a critical factor that impacts equipment longevity, maintenance cycles, and overall system performance. The wrong liner can lead to premature wear, unplanned downtime, and increased operational costs. This guide examines the performance characteristics, application suitability, and lifecycle implications of rubber and metal linings, offering decision-makers a practical framework for selecting the most suitable material for their abrasive slurry pump system.

The Science of Wear: What Abrasive Slurries Do to Pumps

In abrasive slurry pumping environments, material degradation is a direct result of complex mechanical and chemical interactions between the slurry and the pump’s internal surfaces. Two primary wear mechanisms,abrasive wear and corrosive wear,are responsible for most failures in abrasive slurry pump systems.

Abrasive wear occurs when hard particles suspended in the slurry stream physically grind against the pump’s linings, impellers, and casings. The severity of this wear depends largely on the properties of the particles themselves. Larger, angular particles traveling at high velocities are particularly destructive. As they collide with pump surfaces, they remove material layer by layer, reducing the integrity and efficiency of the system over time.

Corrosive wear, on the other hand, involves chemical reactions between the slurry’s fluid component and the pump materials. In many industrial applications, especially in mining or chemical processing, slurries contain acidic or chemically aggressive fluids. When corrosion and abrasion occur simultaneously, the result is accelerated material loss, often at a rate much faster than that of abrasion alone. This dual action makes material selection a critical consideration for slurry pump manufacturers.

Particle size, shape, and velocity all play a critical role in determining the rate and pattern of wear. Spherical particles typically cause less damage than sharp-edged particles. Similarly, low-velocity flows reduce impact force, but high-velocity slurry streams increase both abrasion and erosion, especially in areas where flow changes direction or encounters obstructions.

Turbulence inside the pump further amplifies wear. In particular, impingement, where particles strike surfaces at acute angles, causes significant erosion in critical zones, such as the volute and impeller eye. Micro-cavitation,the formation and collapse of vapor bubbles,can create localized high-pressure impacts, weakening the lining and increasing its susceptibility to wear.

These wear dynamics have a significant impact on the operational life of an abrasive slurry pump. Frequent maintenance, unscheduled downtime, and reduced pumping efficiency are common consequences when wear mechanisms are not fully accounted for during design and material selection. For this reason, leading slurry pump manufacturers invest heavily in material testing and wear modeling to optimize performance and extend pump longevity in demanding slurry pumping conditions.

Performance Under Pressure: How Rubber and Metal Behave Differently

The internal lining of an abrasive slurry pump plays a critical role in managing wear and ensuring pump longevity. Two commonly used materials,rubber and metal,respond to operational stresses in distinct ways, directly influencing their suitability for specific slurry pumping conditions.

Rubber linings are known for their flexibility and energy-absorbing properties. When abrasive particles strike a rubber-lined surface, the material deforms slightly, dissipating the impact energy. This deformation reduces the cutting and gouging effects of sharp particles, especially in applications where impact wear is dominant. Rubber also offers excellent resistance to corrosive fluids, making it a preferred choice in acidic or chemically aggressive slurry environments. In low- to moderate-velocity flows carrying fine or semi-angular particles, rubber-lined abrasive slurry pumps often outperform metal alternatives in terms of wear life and maintenance frequency.

Metal linings, by contrast, are selected for their high hardness and superior resistance to cutting, gouging, and high-velocity erosion. Common materials include high-chrome white iron and hardened steel alloys, which are designed to withstand intense sliding and scouring forces. Metal linings do not deform under impact, which makes them well-suited for handling coarse, dense, or angular solids at high velocities, conditions where rubber would wear rapidly or tear. However, metal linings can be brittle and are more prone to cracking under sudden impact or in applications with inconsistent flow conditions.

In practical slurry pumping applications, the dominant type of wear,impact vs. sliding,determines the optimal material. Rubber is more effective in managing repeated impacts and absorbing vibration, while metal excels in continuous sliding environments where abrasive particles flow along the surface under high pressure.

Different slurry types further influence material behavior. For example:

- Sand slurries, with sharp and coarse particles, often favor metal-lined pumps due to their aggressive cutting action.

- Fly ash, being fine and less angular, may be effectively handled with rubber linings.

- Tailings vary in particle size and chemistry, requiring a balanced assessment of impact and corrosion resistance.

- Cement slurries, which can be both chemically aggressive and abrasive, pose challenges to both materials and often require consultation with experienced slurry pump manufacturers to determine the best fit.

Application Mapping: Matching Liner Type to Operational Realities

Selecting the appropriate liner material for an abrasive slurry pump requires a close evaluation of the operating environment. Rubber and metal linings offer distinct advantages depending on various factors, including flow rate, chemical exposure, temperature range, and duty cycle. Understanding how these factors interact with pump performance is crucial for selecting the proper material in demanding slurry pumping applications.

Flow rate and velocity are primary considerations. At low to moderate velocities, rubber linings excel in absorbing impact and mitigating particle damage through energy dissipation. However, in high-velocity systems where slurry moves rapidly and produces significant sliding abrasion, metal linings are typically preferred. The hardness of metal surfaces withstands continuous scouring and erosion better than flexible materials, making them ideal for high-flow-rate environments where fine tolerances must be maintained.

pH and chemical compatibility also influence the choice of lining. Rubber, especially certain synthetic elastomers, offers excellent resistance to acidic and mildly alkaline slurries, making it suitable for use in chemical processing, handling mine tailings, and wastewater treatment. Metal linings, particularly those made of high-chrome alloys, can resist corrosion but may degrade more rapidly in low-pH environments. In applications with aggressive chemical content, slurry pump manufacturers often recommend rubber linings to reduce the risk of chemical attack.

Temperature extremes present different challenges. Rubber linings typically perform within a limited temperature range, often up to 80–90°C, depending on the compound. Prolonged exposure to high temperatures can lead to hardening, cracking, or delamination of the material. Metal linings, while more tolerant of elevated temperatures, can suffer from thermal fatigue if subjected to repeated heating and cooling cycles. This is common in processes with variable loads or start-stop operations, where thermal cycling introduces mechanical stress and may cause cracking over time.

Pump size and duty cycle further refine material selection. For large pumps operating continuously in high-load environments, metal linings provide durability and consistent wear. In contrast, smaller pumps with intermittent use, common in mobile systems or backup installations, may benefit from rubber linings due to their vibration-damping and lower wear rates under fluctuating conditions.

Lifecycle Thinking: Total Cost of Ownership Beyond Initial Purchase

When evaluating an abrasive slurry pump, the initial purchase price tells only part of the story. Long-term cost-effectiveness depends on multiple operational variables, including wear rates, maintenance requirements, energy efficiency, and system optimization. For asset-intensive industries, selecting the right lining material is a strategic decision directly linked to the pump’s lifecycle cost and overall return on investment.

Slurry pump manufacturers often use Mean Time Between Failure (MTBF) as a core metric for comparing pump designs and liner materials. MTBF is calculated based on historical performance data under defined operating conditions, taking into account variables such as slurry abrasiveness, flow velocity, and chemical composition. Metal-lined abrasive slurry pumps generally offer a higher MTBF in high-velocity, coarse-particle applications, while rubber-lined units often perform better in corrosive or lower-impact environments. The correct pairing of material to operating condition directly affects pump longevity and replacement intervals.

Maintenance cycles also play a significant role in lifecycle cost. Rubber liners are typically lighter and easier to replace, which can reduce labor time and minimize downtime during scheduled maintenance. Metal liners, while more durable in many cases, are heavier and may require additional handling equipment or extended service windows. Downtime costs can add up quickly, especially in continuous-process industries such as mining, wastewater treatment, or power generation, where every hour of unplanned shutdown significantly impacts productivity.

Energy consumption is another key factor influenced by liner type. The internal surface condition and hydraulic profile of a pump determine its operating efficiency. Over time, as liners wear, surface roughness increases, causing higher friction losses. Rubber linings may initially contribute to smoother flow paths, but metal linings tend to maintain their shape and internal dimensions longer under extreme wear conditions. Selecting the right lining can therefore reduce the energy required for slurry pumping, leading to lower operational expenses over the pump’s lifespan.

From an ROI perspective, wear life is just one piece of the puzzle. The true value of a well-selected abrasive slurry pump lies in its ability to stay optimized, maintaining consistent performance with minimal intervention. When pump systems operate within their ideal wear and flow range, operators benefit from reduced energy consumption, fewer emergency shutdowns, and lower long-term maintenance spend. Leading slurry pump manufacturers often provide lifecycle cost models and support tools to help buyers quantify these benefits during the selection process.

Innovation Spotlight: New Developments in Liner Material Technologies

As operational demands on abrasive slurry pumps continue to grow, so does the need for more resilient and application-specific liner materials. Traditional rubber and metal linings, although still widely used, are being enhanced through advancements in materials science. These innovations aim to enhance wear resistance, extend service life, and improve system reliability in a wide range of slurry pumping environments.

Recent advancements in synthetic elastomers and reinforced rubber compounds have significantly improved the performance of rubber-lined slurry pumps. Modern rubber formulations offer enhanced resistance to chemical attack, tearing, and fatigue under cyclical stress. Reinforced elastomers, often embedded with fibers or mineral fillers, provide greater structural integrity and dimensional stability, making them suitable for demanding slurry conditions involving acidic fluids or fine abrasives. These materials are particularly effective in minimizing liner deformation and improving impact absorption.

On the metal side, hard-facing alloys and chrome-coated liners have become industry standards for high-wear applications. High-chrome white iron, for example, is widely used for its extreme hardness and ability to withstand cutting and sliding wear from coarse particles. Chrome coatings applied through thermal spray or electroplating enhance corrosion resistance without compromising abrasion protection. These developments allow slurry pump manufacturers to offer metal-lined solutions that deliver longer wear life while reducing maintenance frequency.

Top slurry pump manufacturers are actively pushing material boundaries by investing in R&D and developing proprietary liner formulations. Some are engineering wear parts with optimized microstructures for controlled erosion, while others are testing new thermal treatment processes to increase hardness without introducing brittleness.

Composite and hybrid linings are also emerging as a promising direction in slurry pumping. These solutions combine the advantages of multiple materials,such as a rubber base with ceramic inserts or a metal shell with polymer overlays,to address specific wear patterns or operating challenges. By integrating materials with complementary properties, composite liners provide targeted protection where it’s needed most, while maintaining flexibility or corrosion resistance in less demanding zones.

These material innovations are reshaping how engineers and operators approach abrasive fluid handling, offering new options that improve the reliability and efficiency of abrasive slurry pump systems across industries.

Decision-Making Framework: How to Choose the Right Lining Material

Choosing between rubber and metal for an abrasive slurry pump lining involves more than a basic material preference. It requires a structured evaluation of the pumping environment, slurry characteristics, and operational goals. A systematic approach ensures that the selected material will support long-term reliability, minimize unplanned downtime, and align with budget constraints.

Start by addressing the key questions:

- What is the particle size, shape, and hardness of the slurry?

- Is the slurry chemically aggressive or neutral?

- What are the expected flow velocities and pressures?

- Will the pump operate continuously or intermittently?

- What are the expected maintenance intervals and acceptable downtime windows?

These questions help define the operating parameters that influence wear patterns and material stress. A fine, chemically aggressive slurry moving at moderate velocity may favor a rubber-lined abrasive slurry pump, while coarse, angular solids in a high-flow system may require the hardness of a metal liner.

Use the following checklist to guide the evaluation process:

- Slurry Properties: Particle composition, pH level, solids concentration, and temperature

- Operating Environment: Velocity, pressure, duty cycle (continuous vs. intermittent), and thermal cycling

- Maintenance Goals: Ease of liner replacement, access limitations, labor availability

- Budget Considerations: Initial investment, lifecycle cost, spare parts availability

While general guidelines are useful, some slurry pumping applications present unique challenges that require engineered solutions. In such cases, consulting with experienced slurry pump manufacturers is essential. Manufacturers often conduct wear analysis, simulate flow conditions, and recommend custom liner materials based on historical data and test results.

By using this framework, plant operators and engineers can make informed decisions that balance performance, maintenance, and cost, ensuring their abrasive slurry pump system is properly equipped for the task at hand.

Turning Material Selection into Long-Term Operational Gains in Abrasive Slurry Pumping

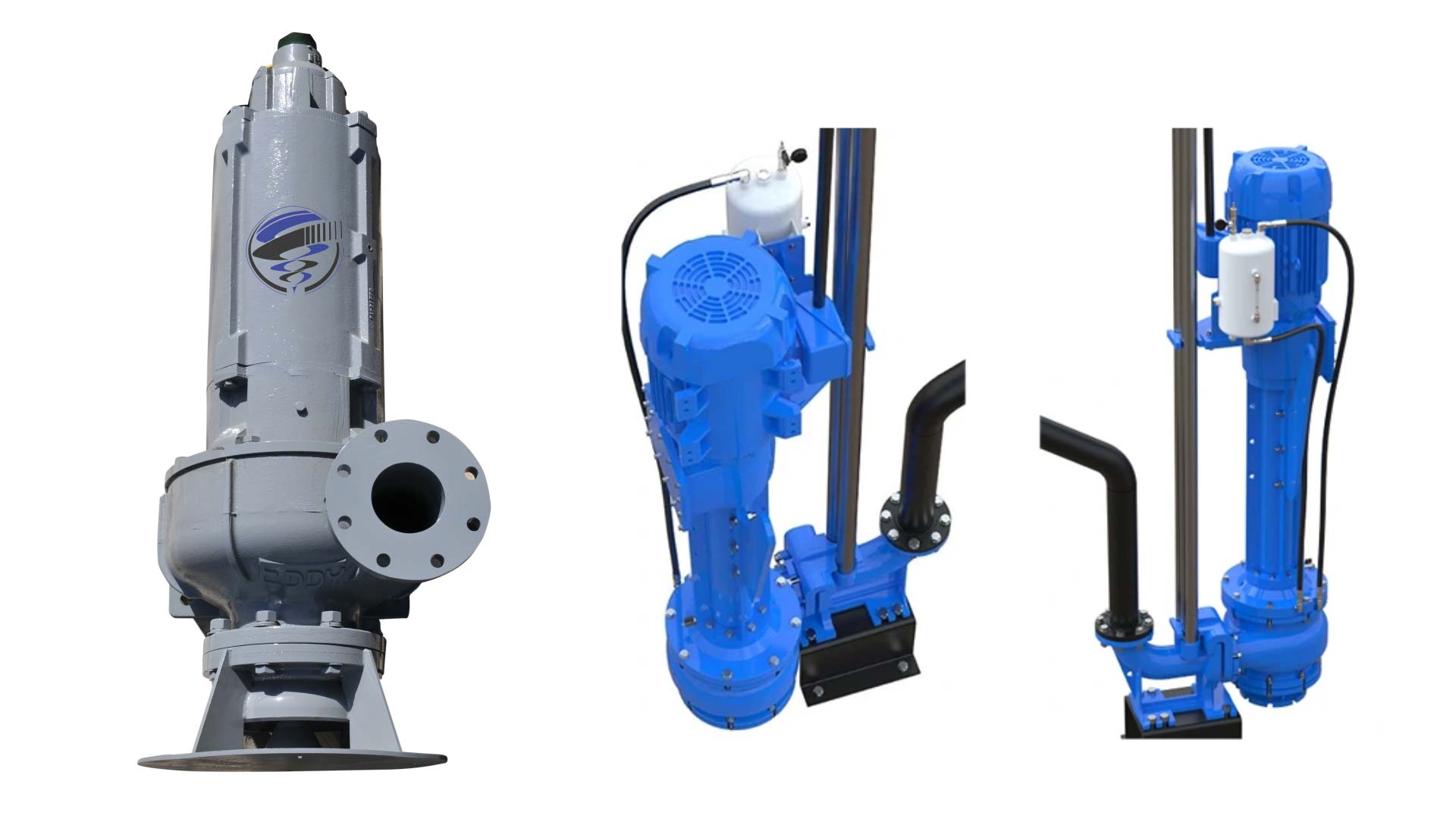

Selecting the appropriate lining material is not just about reducing wear; it’s about improving pump uptime, maximizing return on investment, and maintaining consistent performance in demanding slurry environments. By understanding the behavior of rubber and metal under specific operating conditions, operators can make smarter decisions that reduce maintenance and enhance operational efficiency. For expert guidance, equipment recommendations, or customized slurry solutions, connect with the team at Dredging NJ, your trusted partner in reliable, heavy-duty slurry pumping and dredging services.