Introduction: Why Equipment Selection Defines Project Success

Every successful marine or inland restoration project depends on one critical decision — the right choice of equipment, whether restoring navigation channels, cleaning lagoons, or maintaining ports, dredging and dewatering operations form the foundation of waterway management and environmental rehabilitation.

When equipment is well-matched to the project conditions, it delivers cleaner results, faster timelines, and reduced costs. But when equipment is mismatched, even the best crews face downtime, inefficiency, and compliance risks.

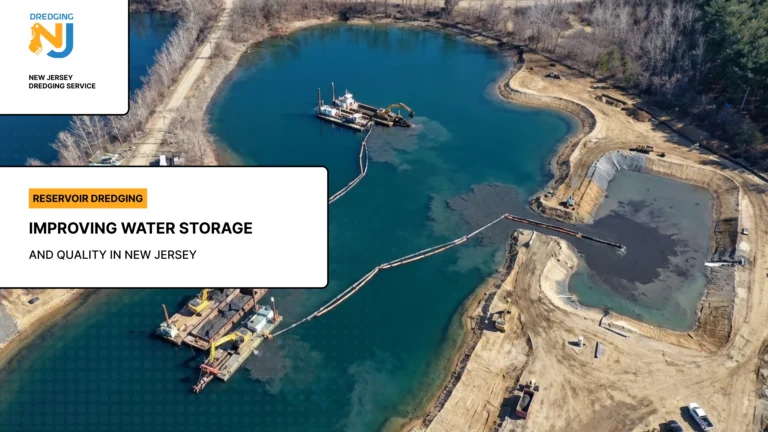

At New Jersey Dredging Services, we’ve seen firsthand how technology, site analysis, and experience transform complex sediment removal projects into streamlined operations. The right combination of dredging systems, pumps, and dewatering service solutions ensures both productivity and environmental protection.

This blog explores how to choose the right tools for dredging and dewatering, from core machinery to smart monitoring systems — and why partnering with a professional dredging service provider is the key to long-term success.

Understanding the Fundamentals of Dredging and Dewatering

To select the right setup, it helps to understand what dredging and dewatering actually entail and how they complement each other.

- Dredging is the process of excavating sediment, silt, and debris from the bottom of water bodies using specialized pumps or mechanical excavators.

- Dewatering is the separation of solid and liquid components of the dredged material, typically to prepare it for reuse or disposal.

These two processes are inseparable. Dredging extracts the material; dewatering ensures it’s handled efficiently. Together, they enable cleaner water, restored capacity, and environmentally responsible sediment management.

In many New Jersey projects — from industrial lagoons to municipal retention basins — dredging and dewatering work hand in hand. A properly designed system ensures continuous flow, minimal clogging, and compliance with discharge regulations. That’s why an experienced dewatering service provider evaluates sediment composition, water chemistry, and site constraints before selecting the right equipment.

Key Challenges in Modern Dredging Operations

Despite technological advances, dredging and dewatering projects face recurring challenges that affect both efficiency and safety.

1. Sediment Variability

Not all sediments behave the same way. Fine silt behaves differently from dense sand or sticky clay. Equipment selection must consider particle size, cohesiveness, and abrasiveness. Cutterhead dredges, for example, are ideal for compact materials, while hydraulic systems are suited to fine slurries.

2. Site Accessibility

Tidal ranges, shallow channels, and limited land access complicate equipment mobilization. Lightweight submersible pumps and modular dredges are preferred when space is constrained.

3. Environmental Regulations

Strict NJDEP and EPA standards govern New Jersey’s coastal and inland dredging sites. Choosing efficient, low-emission engines and closed-loop water systems helps maintain compliance.

4. Dewatering Efficiency

Without the right dewatering service, dredged material can overload pipelines or cause delays. Equipment must handle varying flow rates and solids concentrations.

Understanding these challenges underscores why dredging and dewatering projects benefit from an integrated approach — one in which design, machinery, and operations are synchronized by an experienced dredging service provider.

Essential Equipment for Effective Dredging Projects

Every project has unique needs, but a few core equipment types form the backbone of professional dredging and dewatering operations.

1. Cutterhead Dredges

These machines use rotating blades to loosen compacted sediments before suctioning them through a discharge pipeline.

- Advantages: Excellent for cohesive soils, precise depth control, and continuous operation.

- Applications: River maintenance, port dredging, and lake restoration.

2. Hydraulic Dredges

Hydraulic dredges use suction pumps to transport sediment-laden water directly to the dewatering service site.

- Advantages: Handles large volumes efficiently and maintains steady pumping pressure.

- Applications: Industrial lagoons, tailings ponds, and municipal projects.

3. Submersible Dredge Pumps

Compact yet powerful, these pumps are ideal for confined or shallow areas.

- Advantages: Easy to deploy, portable, and low maintenance.

- Applications: Construction dewatering, pond cleaning, and confined waterways.

4. Amphibious Excavators

Built for versatility, these excavators operate on both land and water.

- Advantages: Mobility in marshlands, flood zones, and soft terrains.

- Applications: Wetland restoration and environmental dredging.

5. Supporting Equipment

Booster pumps, HDPE pipelines, and floats maintain continuous slurry transport. They link the dredge to the dewatering service area while reducing friction losses and system wear.

Together, these machines form the essential toolkit of any professional dredging service. The right combination ensures optimal flow, reduced downtime, and project scalability.

Core Dewatering Equipment and Its Applications

The dewatering stage is where sediment management becomes measurable. Efficient systems separate solids from water, reduce disposal volume, and improve water clarity. Below are the most common tools used by modern dewatering service providers.

1. Geotextile Tubes

Large, permeable fabric containers that let water drain while retaining solids.

- Advantages: Cost-effective, easy to install, and environmentally friendly.

- Applications: Lagoon cleaning, agricultural ponds, and shoreline remediation.

2. Belt Filter Presses

Mechanical presses that compress slurry between rotating belts.

- Advantages: Consistent dryness levels and fast throughput.

- Applications: Wastewater treatment, municipal sludge handling.

3. Centrifuges

High-speed separators that use centrifugal force to split solids from liquids.

- Advantages: Precision and compact footprint.

- Applications: Industrial projects requiring strict discharge standards.

4. Sludge Drying Beds

An older but reliable method that relies on evaporation and natural drainage.

- Advantages: Low cost, simple design, minimal energy use.

- Applications: Small community ponds and temporary dewatering service setups.

5. Polymers and Flocculants

Chemical aids that accelerate sedimentation and improve clarity in discharge water. These are essential components in most professional dredging and dewatering projects.

Each option offers unique benefits. A qualified dewatering service provider selects equipment based on site conditions, budget, and regulatory needs.

Matching Equipment to Site Conditions and Project Goals

No two dredging and dewatering projects are identical. Equipment must be customized to match physical, environmental, and operational factors.

- Sediment Type

Clay-rich materials demand strong cutting power, while fine silt benefits from low-turbulence pumps. Sand requires abrasion-resistant liners and impellers.

- Flow Rate and Distance

For long transport pipelines, booster pumps keep slurry moving smoothly from the dredge to the dewatering service area. Flow monitoring ensures system balance.

- Water Depth and Accessibility

Shallow environments or inland ponds may require portable submersible pumps, while deeper marine zones use larger cutterhead dredges.

- Environmental Sensitivity

Eco-sensitive wetlands and coastal zones need low-impact dredging systems to prevent turbidity and protect aquatic life.

By evaluating these factors, New Jersey Dredging Services ensures each dredging and dewatering project achieves the right balance of power, precision, and environmental responsibility.

Integration Between Dredging and Dewatering Systems

Seamless integration between dredging and dewatering systems is the secret to operational efficiency. When one component underperforms, the entire chain slows down.

- Flow Synchronization: The dredge output must align with dewatering service capacity to prevent overflows.

- Automated Controls: Smart sensors adjust pump speeds to maintain a steady flow.

- Pipeline Design: Proper pipeline diameter and slope reduce friction losses and avoid blockages.

The integration of dredging and dewatering service systems minimizes manual adjustments and maintains continuous sediment transport. At New Jersey Dredging Services, we use telemetry and control panels that provide real-time feedback, allowing operators to make precise decisions.

How Automation and Smart Controls Improve Efficiency

Modern technology is revolutionizing dredging and dewatering. Automation enhances safety, accuracy, and overall project economics.

- Automated Dredge Controls

Digital displays allow operators to view pump performance, slurry concentration, and dredge depth in real time. This reduces guesswork and optimizes material removal.

- GPS and Telemetry Systems

Advanced GPS mapping enables pinpoint dredging accuracy. Telemetry systems transmit live data to project managers, helping them track productivity remotely.

- Energy Optimization

Variable Frequency Drives (VFDs) adjust pump speed based on resistance, lowering fuel use and mechanical wear.

These innovations make dredging and dewatering faster, safer, and more sustainable — aligning with the state’s push toward greener infrastructure. A forward-thinking dredging service provider ensures these tools are integrated into every modern project.

Environmental Compliance and Sediment Management Standards

New Jersey’s waterways and coastal systems require responsible management. Compliance is a key factor in every dredging and dewatering project.

1. Water Quality Standards

All projects must meet NJDEP and EPA discharge guidelines for turbidity and pollutants. Using energy-efficient pumps and enclosed dewatering service setups ensures compliance.

2. Sediment Disposal

Once material is dewatered, solids are tested and either reused, stabilized, or disposed of at approved facilities. Proper handling reduces reliance on landfills and contamination risk.

3. Sustainable Practices

Many dredging service companies, including New Jersey Dredging Services, now use biodegradable hydraulic fluids, low-noise engines, and eco-friendly dredge heads.

4. Monitoring and Reporting

Continuous monitoring of sediment and water quality allows clients to document environmental performance — an important part of sustainable dredging and dewatering.

Adhering to these practices demonstrates commitment not just to compliance but to environmental stewardship.

Cost Considerations and Return on Investment

Choosing the right dredging and dewatering equipment impacts both short-term costs and long-term value. The cheapest option isn’t always the most cost-effective.

- Reduced Downtime

Durable equipment with integrated control systems prevents delays caused by clogging or breakdowns.

- Lower Maintenance

Corrosion-resistant materials and efficient hydraulics extend service life and reduce maintenance expenses.

- Optimized Manpower

Automation means fewer people are needed for operation, reducing labor costs.

- Regulatory Savings

Projects that stay compliant avoid costly fines and rework. A professional dredging service helps ensure all systems meet regulatory expectations from day one.

In the long run, properly sized equipment and expert management can save thousands in operational costs — proving that quality dredging and dewatering systems offer measurable ROI.

Partnering with a Professional Dredging and Dewatering Service

Technology alone can’t guarantee success. Experience matters. Working with an established dredging service or dewatering service provider ensures precision, reliability, and accountability.

- Technical Expertise

Professional teams understand fluid dynamics, sediment transport, and regional conditions. They can troubleshoot issues before they become costly delays.

- Tailored Solutions

New Jersey Dredging Services customizes equipment selection based on project goals, environmental sensitivity, and budget — ensuring perfect alignment between dredging and dewatering.

- Maintenance and Support

Ongoing maintenance and technical support keep systems performing at peak efficiency throughout the project lifecycle.

- End-to-End Management

From planning and permitting to final disposal, a trusted partner manages every stage of your dredging and dewatering operation — saving time and ensuring quality.

With the right partnership, clients gain more than equipment — they gain confidence and control.

Real-World Applications Across New Jersey

The versatility of dredging and dewatering makes it applicable to many sectors across the state.

- Municipal Lagoons: Restoring stormwater and wastewater lagoons by removing settled sludge.

- Ports and Marinas: Maintaining navigable depths to support tourism and trade.

- Construction Projects: Controlling groundwater and removing sediment from foundation excavations.

- Environmental Restoration: Cleaning contaminated sediments to restore wetlands and habitats.

Each scenario benefits from customized dredging service and dewatering service strategies, designed to meet specific regulatory and operational needs.

Future Trends in Dredging and Dewatering Technology

Innovation continues to drive efficiency and sustainability in dredging and dewatering operations.

- Hybrid and Electric Dredges: Lower emissions and reduced operating costs.

- AI-Driven Monitoring: Predicts wear patterns, automatically adjusts flow rates, and minimizes energy use.

- Improved Geotextile Materials: Enhanced permeability for faster drying and cleaner effluent.

- Closed-Loop Systems: Enable near-zero discharge by recycling process water.

By staying ahead of these trends, New Jersey Dredging Services ensures its dredging and dewatering solutions remain efficient, compliant, and future-ready.

Conclusion: Building Long-Term Efficiency with the Right Equipment

Selecting the right equipment for dredging and dewatering is not just a technical decision — it’s a strategic investment. From sediment type to discharge standards, every factor influences which dredge, pump, or dewatering service solution will yield the best results.

An experienced dredging service provider bridges the gap between theory and execution, ensuring each project runs efficiently, safely, and sustainably. When dredging and dewatering are managed as a unified system, clients achieve cleaner outcomes, lower costs, and greater environmental compliance.

Partner with New Jersey Dredging Services

Looking to optimize your next dredging and dewatering project?

New Jersey Dredging Services offers comprehensive solutions — from on-site consultation and equipment selection to operation and maintenance.

Our expert team provides reliable dredging and dewatering services, backed by years of local experience and state-compliant technology.Contact New Jersey Dredging Services today to schedule a consultation and learn how our customized dredging and dewatering systems can make your next project cleaner, faster, and more cost-effective.