Selecting and operating the right dredging equipment is a strategic decision that directly impacts project efficiency, environmental compliance, and cost control. With a wide range of dredge equipment options—from compact lake dredging systems to high-capacity cutter suction dredgers—choosing the ideal configuration depends on thorough planning, sediment analysis, and expert consultation. Incorporating advanced tools like GPS monitoring, automation software, and booster pumps further enhances precision and performance. Whether the goal is sediment removal, land reclamation, or ecological restoration, investing in the right equipment ensures a smooth, sustainable dredging operation from start to finish.

Understanding the Role of Dredging Equipment

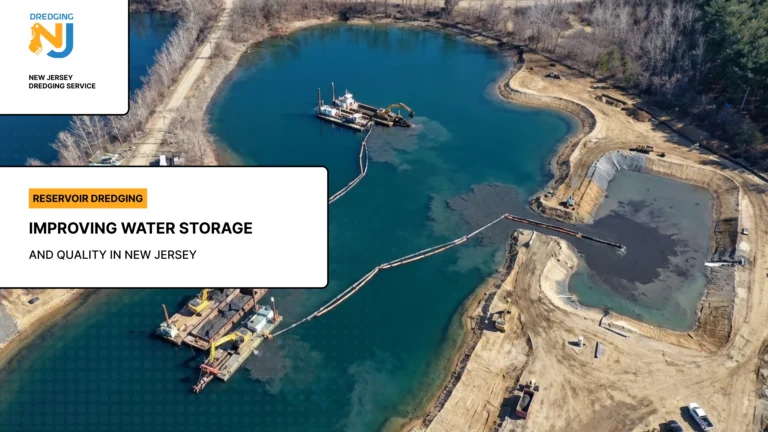

Dredging equipment plays a central role in shaping, maintaining, and restoring both marine and inland water environments. From deepening shipping channels and removing accumulated sediment in harbors to restoring freshwater ecosystems, this specialized machinery is vital to numerous industries. Whether the goal is to improve navigation, reclaim land, or remediate contaminated sites, effective dredge equipment is often the difference between project success and costly delays.

Each dredging project presents unique challenges based on the environment, sediment type, water depth, and project objectives. Accordingly, different dredging methods require specific types of dredging equipment. For instance, environmental dredging in sensitive lakebeds may require low-turbidity tools and precision-controlled systems, whereas large-scale port maintenance may utilize heavy-duty cutter suction dredgers. In lake dredging applications, compact and maneuverable dredgers are preferred to minimize shoreline disruption and operate efficiently in shallow or confined areas.

The core distinction between hydraulic and mechanical dredging also influences equipment selection. Hydraulic dredging uses pumps and pipelines to transport sediment-laden water (slurry), making it ideal for large volumes over extended distances. This method typically relies on components like cutterheads, dredge pumps, and booster stations. In contrast, mechanical dredging involves direct lifting and removal using buckets, clamshells, or backhoes, suitable for coarse material or where precise excavation is needed.

Selecting the right dredging equipment requires evaluating several key factors: the physical characteristics of the material being dredged, waterbody constraints (depth, current, debris), environmental regulations, and the intended use of the dredged material. Projects involving lake dredging equipment, for example, may prioritize ease of deployment and low environmental impact, while coastal or riverine operations may demand more robust, high-capacity dredgers. Matching the dredge equipment to the project ensures optimal performance, minimal downtime, and compliance with regulatory and environmental requirements.

Primary Components of a Dredging System

A successful dredging operation depends on a coordinated system of specialized components, each playing a critical role in sediment removal and transport. Understanding the core elements of dredging equipment helps project managers select the right configuration for their operational needs, whether in open coastal waters or controlled environments like lakes and reservoirs.

Dredge Platform

The dredge platform serves as the foundation of any dredging system, housing key operational equipment. Several types are available based on the application. Cutter suction dredgers (CSDs) are commonly used for hard-packed materials and can operate continuously using a rotating cutterhead. Hopper dredgers are self-propelled vessels that store dredged material onboard and discharge it at a disposal site. Auger dredgers, ideal for lake dredging equipment needs, use a horizontal cutter to precisely remove material with minimal turbidity, making them suitable for environmental or confined projects. Each platform type is selected based on water depth, material type, and disposal method.

Cutterheads

Mounted on the front of the suction pipe, cutterheads are critical for breaking up compacted or cohesive sediments. Plain cutterheads are best for soft materials like clay and silt, while toothed cutterheads are used for denser materials such as sand, gravel, or even rock. The rotating motion of the cutterhead agitates and loosens the seabed, allowing the dredge pump to suction the slurry effectively. Cutterhead selection impacts excavation efficiency and must be tailored to the sediment profile and environmental restrictions of the project site.

Dredge Pumps

The powerhouse of any dredging system, dredge pumps are designed to transport sediment-water mixtures through pipelines. These high-capacity pumps must withstand abrasion, pressure fluctuations, and long operating hours. When choosing this component of dredging equipment, key factors include pump size, impeller design, material composition (such as high-chrome alloys), and flow rate. Dredge pumps are particularly crucial in lake dredging equipment setups where the distance to the discharge point may be shorter, but sediment characteristics vary significantly.

Pipelines and Discharge Systems

Once slurry is pumped from the dredging site, it is conveyed through a network of pipelines to the designated discharge location. Pipelines can be floating, used in open water applications, or submerged, placed along the waterbed for stability and environmental control. Discharge systems include nozzles, spreaders, and diffusers that control the sediment placement, whether into containment areas or for land reclamation. Proper alignment and durability of these discharge systems are vital for maintaining consistent slurry flow and avoiding costly blockages or spills.

Together, these components form the operational core of dredge equipment systems and must be optimized based on project type, water body, and sediment composition.

Specialized Dredge Equipment for Specific Environments

Dredging operations take place in diverse and often challenging environments, requiring tailored solutions that go beyond standard setups. Specialized dredging equipment is designed to meet these situational demands—whether navigating tight spaces, operating in ecologically sensitive zones, or tackling shallow, marshy terrain. Matching the right dredge equipment to the jobsite ensures efficiency, minimizes disruption, and delivers more precise results.

Lake Dredging Equipment

Projects involving lakes, reservoirs, and canals often face limitations in access, depth, and environmental sensitivity. Lake dredging equipment is specifically engineered to address these challenges. These compact and highly maneuverable dredgers are capable of operating in shallow or confined spaces without disturbing the surrounding shoreline or aquatic habitat. They are often equipped with horizontal augers or small cutterheads that deliver controlled sediment removal while minimizing turbidity. Electric and cable-driven lake dredging equipment is also available for operations where noise and emissions must be kept to a minimum.

Amphibious Dredge Equipment

For wetlands, marshes, floodplains, and shallow water bodies with unstable ground conditions, amphibious dredging equipment offers unmatched versatility. These dredgers are mounted on pontoons or specially designed tracks that allow them to move between land and water seamlessly. They can traverse soft terrain and shallow environments where conventional dredgers would sink or become inoperable. Amphibious dredge equipment is ideal for habitat restoration, flood mitigation, and sediment control in hard-to-reach locations.

Environmental Dredging Tools

In sensitive zones such as contaminated harbors, urban lakes, or protected wetlands, environmental dredging requires equipment designed for precision and low-impact excavation. This specialized dredging equipment includes sealed cutterheads, shrouded suction systems, and precision-positioning tools like GPS and sonar. These features help limit turbidity and prevent the spread of contaminants during sediment removal. Environmental dredge equipment also incorporates real-time monitoring to ensure compliance with regulatory thresholds for water quality and sediment displacement.

Remote-Controlled and Autonomous Dredgers

When safety, cost-efficiency, or access limitations make manned dredging operations impractical, remote-controlled and autonomous dredgers offer a powerful alternative. These systems are compact, lightweight, and operable via radio or satellite link, making them ideal for hazardous or small-scale dredging tasks. They are frequently used in lake dredging equipment fleets to maintain consistent performance without requiring extensive crew deployment. With advancements in onboard sensors and AI-driven navigation, autonomous dredgers are becoming an increasingly valuable asset for modern dredging operations.

Power Systems and Propulsion

Power and mobility are the backbone of any effective dredging operation. The performance of dredging equipment hinges on a dependable and efficient power system, especially when operating under continuous loads or in challenging aquatic environments. From inland lakes to coastal channels, selecting the right propulsion and power configuration ensures the dredge equipment can maintain productivity, positioning accuracy, and overall system integrity.

Diesel vs. Electric Dredge Equipment

The choice between diesel and electric-powered dredging equipment largely depends on project scope, location, and environmental restrictions. Diesel-powered dredgers offer high horsepower and are widely used in large-scale or remote dredging operations where shore power is unavailable. They are favored for their mobility and self-sufficiency, particularly in offshore or deepwater conditions. In contrast, electric dredge equipment is gaining popularity in urban, inland, and lake dredging applications due to its lower emissions, reduced noise, and compatibility with clean energy mandates. Electric systems are especially beneficial for long-term projects in environmentally sensitive areas where minimizing ecological impact is a priority.

Onboard Power Units, Thrusters, and Spud Systems

Modern dredging equipment integrates advanced onboard power units to operate critical systems such as pumps, cutterheads, and winches. These power units must deliver consistent energy to all components, particularly during high-load operations like hard sediment cutting or long-distance slurry transport. To maintain precise positioning, especially in strong currents or confined lake areas, many dredgers use thrusters—propulsion devices that provide lateral movement and enhance maneuverability. For stationary operations, spud systems—vertical piles driven into the bed—anchor the dredger in place, ensuring it remains stable during excavation. These systems are essential for maintaining accuracy and reducing operational drift, particularly in dredge equipment designed for small or restricted water bodies.

Importance of Reliable Power Delivery in Heavy-Duty Dredging Environments

In heavy-duty applications such as harbor deepening, tailings recovery, or lakebed restoration, any lapse in power delivery can halt operations and risk equipment damage. Reliable power ensures uninterrupted slurry transport, efficient sediment cutting, and responsive control of onboard systems. Whether running diesel generators or drawing electric power from the grid, dredging equipment must be engineered with redundancy, overload protection, and easy-access serviceability to withstand the demands of continuous-duty dredging in both freshwater and marine environments.

Booster Pumps: Extending the Reach of Dredging Operations

In dredging operations that require long-distance slurry transport, booster pumps are a critical part of the dredging equipment setup. These high-powered pumps are positioned along the discharge pipeline to maintain consistent pressure and velocity, ensuring that the dredged material reaches its destination without settling or clogging. Booster pumps extend the operational reach of the primary dredge pump, making them essential for projects with extended pipeline runs, elevation changes, or abrasive sediment.

What Booster Pumps Do and How They Work

Booster pumps work in series with the primary dredge pump to sustain the flow of slurry through long or complex pipeline systems. As the initial pressure from the dredge pump drops over distance due to friction and material density, the booster pump re-pressurizes the slurry stream to prevent velocity loss. These pumps are typically mounted on skids or pontoons and powered by diesel or electric motors, depending on site conditions. In lake dredging equipment applications, smaller booster units are often used to keep pipelines clear without disturbing shallow or ecologically sensitive zones.

When and Why to Use a Booster Station in Large-Scale Projects

Booster stations become essential when the dredging pipeline exceeds the effective pumping range of the primary system, typically over 2,000 to 3,000 feet, depending on pipe diameter, slurry concentration, and elevation. In large-scale land reclamation, mining, or harbor deepening projects, booster pumps enable the transfer of massive volumes of sediment over miles. They are also vital when pumping uphill or against strong tidal backpressure. Incorporating booster stations into dredge equipment strategies ensures continuous operation, optimizes fuel and energy use, and minimizes downtime caused by pipeline blockages.

Best Practices for Placement and Pipeline Support with Booster Pumps

Proper placement of booster pumps is key to maintaining efficient flow and avoiding pressure surges or material dropout. Ideally, booster stations should be installed at intervals based on hydraulic calculations that account for sediment size, slurry density, and pipeline friction loss. In lake dredging equipment configurations, the booster pump should be positioned on stable pontoons or land platforms to prevent vibration and allow easy access for servicing. It is also important to monitor flow rates and pump pressure in real time using dredging equipment control systems. Supporting the pipeline with floats or trenching helps maintain consistent flow gradients and protects against mechanical stress and sediment accumulation.

Monitoring, Control, and Automation Technology

Modern dredging equipment has evolved far beyond basic mechanical systems. Today, technology plays a central role in improving precision, reducing environmental impact, and increasing overall efficiency. Integrated monitoring and automation tools are now standard in advanced dredge equipment, offering real-time insights into sediment removal, equipment positioning, and system performance. These innovations are especially valuable in complex or environmentally sensitive applications such as lake dredging equipment operations.

GPS, Sonar, and Flow Meters for Dredge Monitoring

Accurate dredging requires constant awareness of equipment location and sediment levels. High-precision GPS systems provide exact positioning for the dredge platform, cutterhead, and spuds, ensuring the operator stays within the designated work area. Sonar systems deliver sub-bottom profiles and depth readings, allowing crews to monitor dredged volumes and avoid over-excavation or missed zones. Flow meters are used to track slurry movement through discharge pipelines, helping operators maintain optimal flow rates and reduce the risk of sedimentation or pipeline blockages. These tools work together to provide a comprehensive picture of dredging performance, reducing guesswork and improving material handling.

Dredging Control Software and Onboard Automation Systems

Automated dredging systems are revolutionizing how projects are executed. Advanced control software allows operators to program dredging depth, track progress, and make real-time adjustments based on feedback from sensors and instruments. Onboard automation can control swing winches, cutterhead speeds, pump output, and spud operations to improve precision and reduce human error. For lake dredging equipment, automation is particularly useful in shallow or irregular waterbodies where tight maneuvering and delicate excavation are required. These systems not only increase productivity but also extend equipment life by minimizing unnecessary wear.

Real-Time Monitoring for Efficiency and Compliance in Lake Dredging and Environmental Zones

In ecologically sensitive projects such as lake restoration or contaminated sediment removal, real-time monitoring is essential for staying within environmental compliance limits. Dredging equipment outfitted with turbidity sensors, water quality monitors, and silt curtain tracking helps ensure that sediment dispersion and pollutant release remain under control. Operators can receive alerts if thresholds are exceeded, allowing them to adjust operations immediately. In lake dredging equipment scenarios, where wildlife habitats and public health are at stake, these monitoring tools provide critical oversight and accountability.

Maintenance and Service Considerations

Maintaining peak performance and minimizing downtime in dredging operations begins with a proactive approach to servicing and care. Regardless of project size or complexity, dredging equipment must operate under demanding conditions—pumping abrasive materials, handling heavy loads, and enduring constant exposure to water, sediment, and environmental elements. A comprehensive maintenance plan not only protects the investment but also ensures long-term operational reliability, whether in open water or lake dredging environments.

Routine Maintenance for Dredging Equipment

Routine maintenance is essential to prevent premature wear and mechanical failure. Daily and weekly inspections should include checking fluid levels, inspecting hydraulic lines, tightening connections, and cleaning intake areas to avoid blockages. For mechanical dredge equipment, greasing of bearings and inspection of structural welds are critical. In lake dredging equipment applications, where dredgers often operate in shallow, debris-laden environments, regular flushing of pipelines and screens helps prevent sediment buildup. Scheduled oil changes, filter replacements, and cooling system checks further support engine and pump longevity.

Wear Parts: Impellers, Liners, Seals, Cutterheads

Certain components of dredge equipment are considered high-wear parts due to their direct exposure to abrasive slurry. These include impellers, pump liners, mechanical seals, and cutterheads. Impellers must be monitored for erosion or cracking, as damage can significantly reduce pumping efficiency. Liners and seals, especially in the pump housing, degrade over time and must be replaced to avoid leaks or reduced performance. Cutterheads, particularly in sand or gravel-rich environments, should be inspected regularly for tooth damage or wear that compromises cutting ability. Keeping a stock of common wear parts on hand can reduce downtime and keep operations running smoothly.

Long-Term Equipment Lifecycle Planning and OEM Support

Effective dredging equipment management includes not just immediate repairs but long-term lifecycle planning. Tracking engine hours, pump cycles, and replacement intervals allows for predictive maintenance scheduling. This reduces the likelihood of unexpected breakdowns and extends the functional lifespan of the equipment. Collaborating with original equipment manufacturers (OEMs) or certified dealers ensures access to genuine parts, technical support, and software updates. For lake dredging equipment, where custom or compact systems are used, OEM support is especially valuable for maintaining compatibility and performance across evolving project requirements.

Choosing the Right Dredging Equipment for Your Project

Selecting the appropriate dredging equipment for a specific project requires careful evaluation of multiple variables. No two dredging jobs are exactly alike—differences in sediment composition, environmental sensitivity, access limitations, and end-use goals all play a role in determining which dredge equipment will deliver the best performance, safety, and cost-efficiency.

Key Criteria: Project Scope, Sediment Type, Location, Environmental Limits

Start by defining the scope of the project. Is the goal to deepen a port, restore a lake, reclaim land, or remove contaminated sediments? The volume of material to be removed, expected duration, and required discharge distance all influence equipment choice. The type of sediment—whether fine silt, dense clay, loose sand, or gravel—affects cutterhead selection, pump configuration, and wear-part durability. Location constraints such as shallow access, tight shorelines, or offshore currents must also be factored in, especially for lake dredging equipment, which is often used in confined or ecologically sensitive areas. Environmental regulations may dictate acceptable turbidity levels, noise limits, and emissions—all of which should guide decisions around power systems, dredging method (mechanical vs. hydraulic), and equipment size.

Comparing Dredge Platforms and Equipment Compatibility

Choosing the right dredge platform—cutter suction dredger, auger dredger, hopper dredger, or amphibious unit—depends on how well it matches the terrain and material being handled. For instance, cutter suction dredgers are well-suited for dense or compacted sediments, while auger dredgers are ideal for precision work in lakes and canals. Lake dredging equipment typically includes smaller, modular dredgers that can be deployed quickly and transported easily between job sites. It’s also important to assess equipment compatibility: pumps, pipelines, booster stations, and automation systems should integrate seamlessly with the chosen dredge platform to ensure smooth operation and minimize retrofitting needs.

Importance of Consulting with Dredge Experts and Suppliers

Working with experienced dredge equipment suppliers or consulting with industry professionals early in the planning phase can prevent costly missteps. These experts can perform site assessments, recommend equipment configurations, and offer insight on local permitting requirements. For specialized operations such as lake dredging or environmental remediation, expert guidance ensures that the equipment selected not only meets technical requirements but also complies with ecological standards. Partnering with trusted suppliers also provides access to after-sales support, training, and OEM-certified spare parts—all critical for project success.

Conclusion

Selecting and operating the right dredging equipment is a strategic decision that directly impacts project efficiency, environmental compliance, and cost control. With a wide range of dredge equipment options—from compact lake dredging systems to high-capacity cutter suction dredgers—choosing the ideal configuration depends on thorough planning, sediment analysis, and expert consultation. Incorporating advanced tools like GPS monitoring, automation software, and booster pumps further enhances precision and performance. Whether the goal is sediment removal, land reclamation, or ecological restoration, investing in the right equipment ensures a smooth, sustainable dredging operation from start to finish.