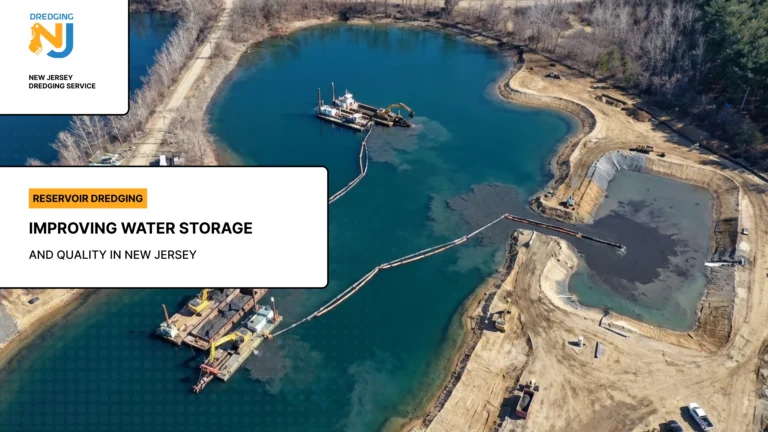

Maintenance dredging refers to the routine removal of sediments and debris from the bottom of waterways to ensure safe and efficient vessel passage. Over time, natural processes like siltation, tidal flows, and stormwater runoff cause sediments to accumulate in navigation channels, berths, and turning basins. This buildup reduces water depth and can severely limit the functionality of ports, harbors, and coastal access points if not addressed regularly.

Ports and terminals situated in dynamic coastal or riverine environments face ongoing sedimentation challenges, especially in high-traffic zones where vessel movement stirs up additional particulate matter. Without timely dredging, these sediments restrict navigation, slow down maritime traffic, and increase the risk of vessel groundings. In severe cases, sediment accumulation may even result in port closures or rerouting of commercial shipping routes, leading to operational delays and increased logistics costs.

The core objective of maintenance dredging is to maintain navigable depths that accommodate the drafts of modern cargo ships, tankers, and passenger vessels. Unlike capital dredging, which involves deepening or widening waterways for new port infrastructure or expansion projects, maintenance dredging is an ongoing activity focused on preserving existing waterway dimensions.

In addition to its role in keeping ports operational, maintenance dredging often intersects with broader coastal management strategies. Dredged materials, when clean and suitable, are frequently repurposed for beach reclamation and shoreline protection projects. This dual benefit supports both navigational safety and environmental sustainability, especially in regions where harbor dredging must align with ecological preservation mandates.

The Science of Sediment Accumulation

Understanding the science behind sediment accumulation is essential to justifying the ongoing need for maintenance dredging. Sediment buildup in ports and harbors is primarily driven by a combination of natural and human-induced factors, all of which contribute to the reduction of navigable depths over time.

Among the natural causes of sedimentation, river inflow plays a significant role. Rivers transport fine particles—such as silt, clay, and organic matter—from upstream areas and deposit them into estuaries and harbor zones where flow velocity decreases. Similarly, tidal action causes bidirectional sediment transport, often pushing coastal materials inland and settling them in low-energy environments like docks and turning basins. Coastal erosion further contributes to the problem by introducing additional sediment from collapsing shorelines, especially during heavy storms or extreme weather events.

Beyond natural forces, port infrastructure is influenced by vessel movement and wave dynamics. Propeller wash, bow waves, and turbulence caused by large vessels can resuspend bottom sediments and redistribute them within the port. This continual churning accelerates the sedimentation cycle, requiring more frequent harbor dredging to restore depth. Additionally, construction activities—such as pier extensions, breakwater installation, or shoreline hardening—can disrupt natural sediment flows and create localized deposition hotspots.

The frequency and volume of sediment accumulation vary based on geography, seasonal hydrology, and human activity. Some active ports may require maintenance dredging multiple times a year to counter rapid shoaling, while others may follow an annual or biennial schedule. Accumulated sediment volumes can reach tens of thousands of cubic meters in a short period, especially in high-traffic shipping lanes or river-fed harbors.

By quantifying and modeling these sedimentation patterns, engineers and port authorities can more effectively plan dredging campaigns, allocate resources, and identify opportunities for beneficial reuse, such as using clean dredged material in beach reclamation projects to stabilize shorelines and restore eroded coastal areas.

Strategic Importance of Maintenance Dredging in Port Operations

The strategic value of maintenance dredging cannot be overstated when it comes to keeping port operations efficient, safe, and economically viable. As global maritime trade increases and vessel designs trend toward larger hulls and deeper drafts, ports must continuously maintain optimal channel depths to remain competitive.

One of the most critical functions of maintenance dredging is its role in preventing vessel groundings. Even minor sediment accumulation in approach channels or berth areas can lead to draft restrictions, forcing vessels to light-load or delay their arrival until safe depths are restored. By removing silt, sand, and debris on a scheduled basis, maintenance dredging helps ensure faster vessel turnaround times, reducing port congestion and demurrage costs.

Modern cargo ships, cruise liners, and naval vessels are larger and require more draft clearance than older models. Supporting growing vessel sizes and deeper drafts demands a consistent maintenance strategy to avoid costly port upgrades. With regular harbor dredging, ports can accommodate Panamax and Post-Panamax vessels without compromising safety or efficiency.

In addition to commercial shipping, maintenance dredging enables consistent access for diverse vessel types—including container carriers, bulk haulers, naval ships, and passenger ferries. This unrestricted access is vital for the movement of goods, national defense operations, and tourism. Ports that fail to maintain navigable waterways risk becoming obsolete or losing traffic to better-maintained alternatives.

Furthermore, the impact of maintenance dredging extends across the entire supply chain. When channels are well-maintained, cargo flows more predictably, loading and unloading operations are optimized, and shipping schedules remain on track. The cumulative effect is a measurable improvement in economic throughput, which translates into increased revenue for ports and reduced costs for importers and exporters.

Operational Planning and Best Practices in Maintenance Dredging

Effective maintenance dredging begins with precise operational planning and continues with the implementation of proven best practices. These processes ensure that sediment removal is both efficient and environmentally compliant, while maintaining the navigability of ports and harbors throughout the year.

Accurate surveys form the foundation of all maintenance dredging operations. Surveying techniques such as single-beam and multi-beam sonar, bathymetric mapping, and sediment sampling help identify the type, volume, and location of accumulated material. These data points are critical for defining dredging scopes, tracking sediment movement, and planning dredge mobilization with minimal disruption to port traffic.

The sedimentation rate, vessel draft requirements, and environmental conditions typically determine dredging schedules. Regular monitoring ensures dredging is performed proactively before depths fall below safe thresholds. Environmental monitoring—including turbidity levels, water quality, and aquatic habitat protection—is essential to mitigate any negative ecological impacts during harbor dredging operations, especially in environmentally sensitive coastal zones.

A variety of dredging equipment is deployed depending on the project site, sediment characteristics, and operational constraints. Cutter suction dredgers are used for compacted or cohesive soils; trailing suction hopper dredgers are ideal for high-volume operations in open harbors and approaches; and clamshell dredgers are effective in confined or urban port settings where precision is required. The right choice of equipment ensures productivity while minimizing wear, fuel consumption, and operational delays.

Modern dredging projects increasingly utilize adaptive management strategies that rely on real-time data to adjust dredging activities as conditions evolve. Real-time dredging optimization tools integrate GPS, sonar feedback, and dredge production metrics, allowing operators to make informed decisions on dredge positioning, cut depths, and cycle timing. This approach improves efficiency and reduces environmental disturbance, particularly in projects where beach reclamation or beneficial reuse of dredged material is planned.

By applying advanced planning tools and adhering to best practices, port authorities and contractors can ensure maintenance dredging is both economically and environmentally sustainable, supporting long-term access and resilience in active harbor systems.

Maintenance Dredging and Its Relationship with Harbor Dredging

Maintenance dredging and harbor dredging are closely interlinked components of comprehensive port management. While maintenance dredging focuses on preserving existing depths, harbor dredging encompasses a broader scope, including the upkeep of key port structures and approach channels. Integrating both practices ensures that ports remain fully operational, safe, and capable of handling a diverse range of vessels under varying maritime conditions.

An essential part of this integration involves the maintenance of berth pockets, turning basins, and navigation channels—areas most susceptible to sediment build-up due to vessel traffic, tidal action, and sediment transport. Keeping these areas clear of obstructions is critical for maneuverability and docking efficiency. Maintenance dredging activities in these zones are typically coordinated with harbor dredging campaigns to avoid operational conflicts and maximize efficiency.

Port authorities bear the responsibility of planning, funding, and overseeing dredging operations. This includes conducting hydrographic surveys, submitting dredging plans, and ensuring regulatory compliance with environmental laws and maritime safety regulations. Permitting agencies often require sediment characterization and environmental impact assessments, especially when dredged materials are intended for beach reclamation or beneficial reuse.

Effective maintenance and harbor dredging programs also require coordination with nearby coastal and municipal stakeholders. These include environmental agencies, coastal zone managers, and local governments who may be affected by dredging operations or may benefit from shared resources, such as clean dredged material for shoreline stabilization or flood mitigation. This collaborative approach helps balance navigational needs with environmental sustainability and community interests.

Together, maintenance dredging and harbor dredging form the backbone of long-term port functionality, ensuring safe transit while supporting regional development and coastal resilience initiatives.

Environmental Considerations and Sustainability

Environmental protection is a critical aspect of every maintenance dredging operation. Ports and dredging contractors must adopt sustainable practices that protect marine ecosystems, comply with regulatory mandates, and align with long-term coastal management goals. With careful planning and modern mitigation tools, it is possible to carry out effective harbor dredging while minimizing ecological disruption.

One of the primary environmental concerns during dredging is turbidity, which refers to the clouding of water due to suspended sediments. Elevated turbidity can harm aquatic life, reduce sunlight penetration, and impact water quality. To mitigate this, contractors use silt curtains—barriers designed to contain suspended particles within the dredging zone. These curtains help limit the spread of turbidity and protect nearby habitats, especially in sensitive estuarine and nearshore environments.

Before any dredging activity begins, sediment testing for contamination is essential. Testing determines the presence of heavy metals, hydrocarbons, and other pollutants. If sediments are found to be contaminated, they must be handled, transported, and disposed of following strict environmental protocols. Conversely, clean sediments may qualify for beneficial reuse, including applications like wetland restoration, levee construction, or beach reclamation, where suitable material is used to rebuild eroded coastlines and improve shoreline resilience.

Managing the fate of dredged material is a balance between environmental safety and cost-effectiveness. Dredged material disposal may involve confined disposal facilities, offshore placement, or upland storage, depending on sediment quality and regional guidelines. When possible, beneficial reuse is the preferred strategy, contributing to sustainable outcomes for both the port and surrounding communities.

All maintenance dredging operations in the U.S. must adhere to stringent regulatory frameworks, including the Clean Water Act (CWA) and the Marine Protection, Research, and Sanctuaries Act (MPRSA). These laws ensure that dredging activities do not adversely impact water quality, marine habitats, or public health. Permitting agencies such as the U.S. Army Corps of Engineers and the Environmental Protection Agency oversee these processes, requiring detailed documentation and environmental assessments before approvals are granted.

By incorporating sustainability measures and regulatory compliance into every phase, maintenance dredging can effectively support navigation needs while protecting the long-term health of coastal and marine environments.

Maintenance Dredging for Coastal Protection and Beach Reclamation

Beyond its core function of maintaining navigable waterways, maintenance dredging plays a pivotal role in coastal protection through its connection to beach reclamation and shoreline management efforts. In regions where sediment transport is dynamic and erosion threatens infrastructure or ecosystems, integrating dredging with coastal resilience strategies offers significant environmental and economic benefits.

One of the most effective approaches is linking maintenance dredging with beach reclamation initiatives. Instead of disposing of dredged material offshore or in containment areas, clean and compatible sediments—especially sand—can be repurposed to replenish eroded beaches. This practice not only offsets shoreline loss but also enhances the recreational and ecological value of coastal zones.

Reusing dredged sand for shoreline stabilization and erosion control has become a best practice in areas experiencing chronic coastal degradation. By placing dredged material in engineered profiles, ports and coastal managers can reinforce dunes, elevate berms, and extend the buffer between inland infrastructure and storm surge. This method reduces the need for hard structures like seawalls and allows for more natural sediment movement.

Sediment redistribution through maintenance dredging supports long-term coastal resilience by restoring natural sediment balances disrupted by development, sea-level rise, or reduced upstream sediment supply. When dredged materials are carefully placed to mimic natural deposition patterns, they can sustain beaches, wetlands, and barrier islands that act as protective buffers during extreme weather events.

Many of these efforts rely on collaborative projects between ports and environmental agencies, combining technical expertise, regulatory oversight, and funding resources. Port authorities, the U.S. Army Corps of Engineers, and coastal conservation groups often work together to identify suitable sediment sources, assess environmental compatibility, and execute reclamation programs that align with both harbor dredging schedules and regional shoreline management plans.

By aligning maintenance dredging with beach reclamation and coastal protection goals, ports contribute not only to safe navigation but also to the preservation of vulnerable shorelines and habitats, creating a win-win for infrastructure and the environment.

Technological Advancements in Dredging Operations

Technological innovation is reshaping the future of maintenance dredging, making operations more efficient, precise, and environmentally responsible. As ports face increasing demands for deeper channels and tighter environmental regulations, the integration of advanced tools and systems has become essential to optimizing both productivity and sustainability.

One of the most significant advancements is the use of real-time dredging monitoring systems. These systems provide continuous feedback on dredge depth, sediment removal rates, and environmental conditions such as turbidity. Operators can monitor dredging performance live, adjust operations instantly, and ensure compliance with environmental standards—all while reducing fuel usage and time on site.

GPS-guided dredging has also revolutionized accuracy and spatial control. By overlaying digital dredging plans onto geospatial coordinates, operators can position dredge heads within inches of the target zone. This precision prevents over-dredging or missed areas and supports efficient harbor dredging, especially in constrained or high-traffic areas where accuracy is critical.

To address ecological concerns, eco-friendly dredging techniques are now more widely adopted. Low-turbidity cutter heads, biodegradable hydraulic fluids, and silt containment technologies reduce the impact on marine ecosystems. These methods are particularly valuable in environmentally sensitive regions or when dredged material is designated for beach reclamation or wetland restoration.

Additionally, automation and data-driven dredge fleet operations are streamlining large-scale maintenance efforts. Dredgers equipped with sensors, automated controls, and AI-driven analytics can adapt to changing site conditions in real time, improving overall efficiency and reducing human error. These technologies enable centralized control of multi-vessel operations and provide actionable insights for future dredging campaigns.

By incorporating these advancements, ports can enhance the precision, efficiency, and environmental performance of their maintenance dredging programs, ensuring that dredging not only meets navigational requirements but also aligns with broader goals of sustainability and coastal resilience.

Challenges and Future Outlook

While maintenance dredging remains essential to the long-term viability of ports and harbors, it faces a range of challenges that demand adaptive strategies and forward-thinking solutions. As environmental, economic, and logistical pressures intensify, port authorities must navigate a complex landscape to sustain operational continuity.

One of the most pressing challenges is the rising rate of sedimentation driven by climate change and human-induced upstream development. Increased rainfall, sea-level rise, and altered river flow patterns contribute to faster sediment deposition in critical navigational zones. Simultaneously, deforestation, agriculture, and construction in upstream watersheds exacerbate the influx of fine particulates, making harbor dredging more frequent and resource-intensive.

Funding and budget limitations pose another significant hurdle. Maintenance dredging is a recurring operational cost, often requiring substantial capital for equipment mobilization, permitting, and sediment disposal or reuse. Many port authorities struggle to secure consistent funding, especially smaller ports that lack the volume to justify large-scale investments. This often results in deferred dredging, putting navigation safety and port competitiveness at risk.

A key balancing act involves minimizing environmental impact while meeting operational necessities. With increasing regulatory scrutiny and public concern over coastal ecosystems, dredging projects must now adhere to more stringent environmental standards. Managing this balance—especially when dredged material is used for beach reclamation—requires advanced planning, stakeholder engagement, and the use of environmentally sound practices.

Looking ahead, innovations are shaping the future of maintenance dredging. From predictive sedimentation modeling and automated dredge fleets to real-time monitoring and hybrid electric equipment, technology is enabling more efficient and sustainable dredging operations. Ports that adopt these advancements can not only reduce environmental footprints but also improve long-term planning, cost forecasting, and asset management.

As the maritime industry evolves, so too must the strategies that underpin maintenance dredging. Addressing these emerging challenges with innovation, collaboration, and resilience will be critical for ensuring the continued functionality of global port infrastructure.

Conclusion

Maintenance dredging is a foundational element of modern port operations, ensuring that critical waterways remain navigable, efficient, and safe for commercial, military, and passenger vessels. By routinely managing sediment accumulation through precision techniques and adaptive scheduling, ports can prevent costly delays, vessel groundings, and depth restrictions. The integration of maintenance dredging with harbor dredging initiatives and beneficial reuse strategies, such as beach reclamations, further extends its value, supporting not only maritime logistics but also coastal protection and environmental sustainability.

As sedimentation rates rise due to climate change and development pressures, and as ports face tighter environmental regulations and budget constraints, the importance of innovation and strategic planning becomes even more apparent. From advanced monitoring systems to eco-conscious dredging methods, the industry is evolving rapidly to meet these demands. By embracing data-driven decision-making, collaborative coastal management, and emerging technologies, stakeholders can ensure that maintenance dredging continues to deliver long-term operational and ecological benefits for ports and surrounding communities.